- Service Name: Flooded Member Detection (FMD)

Flooded Member Detection (FMD) system is a reliable and cost-effective method to detect flooded members on subsea platform and structures.

Oil & Gas platforms periodically require critical members of its structure to be inspected on a regular basis for any anomalies. Any cracks, leaks and other damage defects to structural members could allow water to ingress and potentially lead to structural failures over time. This can be prevented by conducting flooded member detection (FMD) inspections.

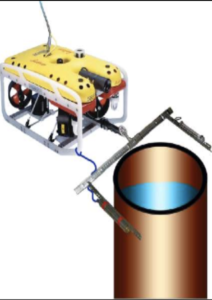

The Gamma Flooded Member Detection (FMD) system uses Caesium 137 radioactive source inspection technology. It is mounted on a frame which is carried by the remotely operated vehicles (ROVs), to facilitate the inspection of underwater structures. All readings are in real time and reported on site.

The frame of our FMD system is built out of high-grade aluminium with stainless steel fittings to provide outstanding strength while remaining lightweight. In this way, it can be adapted to fit a wide range of ROVs, ranging from the smallest observation ROV to the largest, work-class ROV.

The system does not need members to be cleaned prior to the survey. All readings are reliable and accurate and obtained within seconds. This makes the Enspek FMD particularly cost effective and time efficient.

System Advantage:-

- System rated to be operable up to 5000 feet.

- Adjustable frame to accommodate members size from 200mm to 2000mm.

- Can inspect Vertical, Horizontal or Angled support members.

- Requires no marine growth removal for detection

- Detection speed in seconds per member.

- Results available in real time (with a detailed report supplied post survey)

- Highly sensitive detector capable of more than 1 million counts per second.

- System may be diver or ROV deployed.

- Adjustable mounting plate for different ROV attachments.

- Lightweight in air of 20kg

- Robust and reliable communication system.

- Twisted pair or optical communication options.

- Low system power consumption, requiring only 24 VDC from the host vehicle.

- System can be battery operated for up to 20 hours.

- Small footprint for surface equipment.

- Multiple levels or safety employed for system hardware.

- Equipment packed in compact Pelicase© for ease of transportation.

- 100% redundancy of equipment spread

- Professionally trained and experienced operators

- Lloyd’s Register approved inspection

Three reasons to call Enspek for your FMD services.

- Enspek FMD uses the latest technology to obtain reliable quality data.

- Our personnel respond quickly to your needs and provide you with immediate results.

- Enspek FMD services are extremely cost effective compared to our competitors.

Enspek FMD has developed its own propriety acquisition and reporting software. The components data is logged into the software prior to the survey and are then grouped in sizes relative to the frame configuration to generate an efficient inspection programme. Calibration of air and water counts taken prior to each dive are entered into the software which then provides the operator with a real time predicted dry or flooded status. At this moment, the operator will be given an unambiguous diagnosis of each component, which is automatically logged into the software for post inspection reporting. Any anomalies found are discovered in real-time, with a detailed report supplied post survey.

Please wait while flipbook is loading. For more related info, FAQs and issues please refer to DearFlip WordPress Flipbook Plugin Help documentation.