Flooded Member Inspections

GAMMA FMD Subsea Unit

Flooded Member Detection (FMD) system is a reliable and cost-effective method to de- tect flooded members on subsea platform and structures.

Why Choose Our Service?

Oil & Gas platforms periodically require critical members of its structure to be inspected on a regular basis for any anomalies. Any cracks, leaks and other damage defects to structural members could allow water to ingress and potentially lead to structural failures over time. This can be prevented by conducting flooded member detection (FMD) inspections.

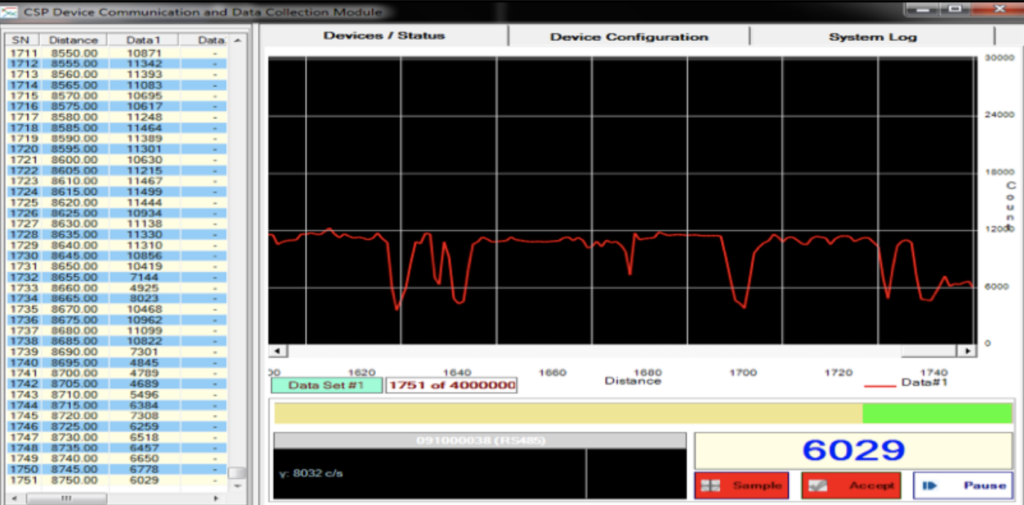

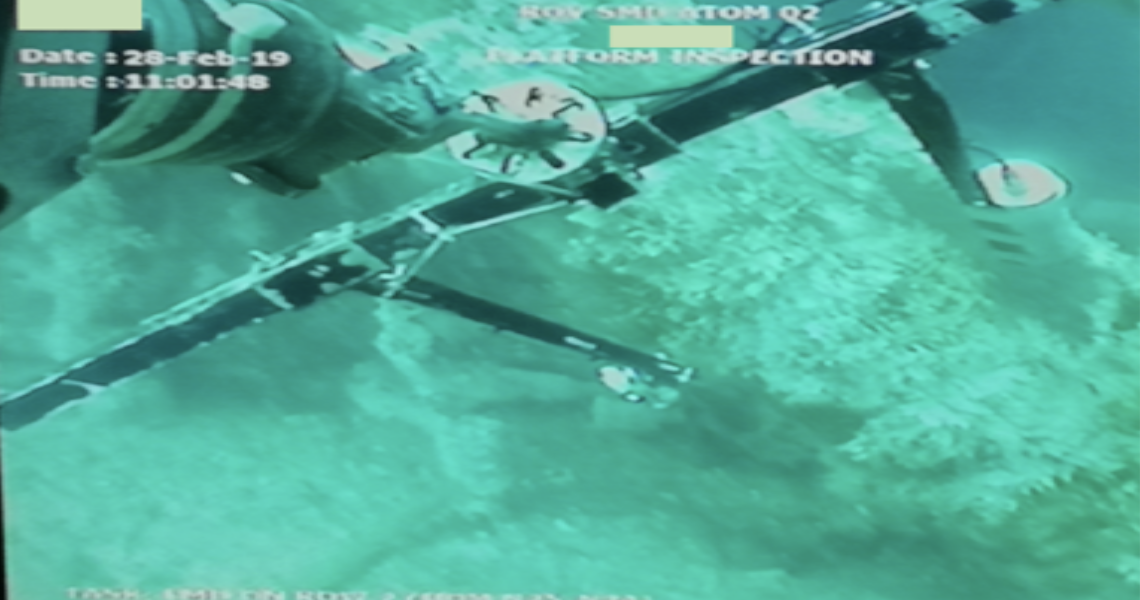

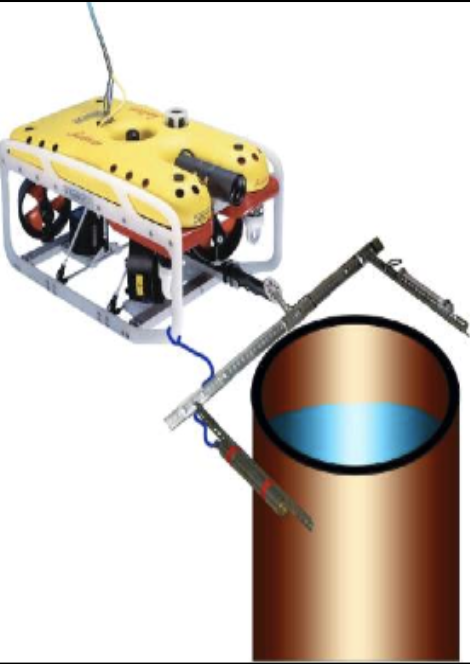

The Gamma Flooded Member Detection (FMD) system uses Caesium 137 radioactive source inspection technology. It is mounted on a frame which is carried by the remotely operated vehicles (ROVs), to facilitate the inspection of underwater structures. All read- ings are in real time and reported on site.

The frame of our FMD system is built out of high-grade aluminium with stainless steel fit- tings to provide outstanding strength while remaining lightweight. In this way, it can be adapted to fit a wide range of ROVs, ranging from the smallest observation ROV to the largest, work-class ROV.

The system does not need members to be cleaned prior to the survey. All readings are reliable and accurate and obtained within seconds. This makes the Enspek FMD particularly cost effective and time efficient.

Why Deploy Enspek FMD Solutions?

Cost Savings

Accurate, Reliable and Repeatable

Efficient and Effective

Real-time Results

Low Risk

Three reasons to call Enspek for your FMD services.

❖ Enspek FMD uses the latest technology to obtain reliable quality data.

❖ Our personnel respond quickly to your needs and provide you with immediate

results.

❖ Enspek FMD services are extremely cost effective compared to our competitors.